About eletro galvanizing coil

Electro galvanized steel is a process in which a layer of zinc is bonded to steel in order to protect against corrosion. EGI steel sheet is manufactured by electroplating a pure zinc coating on one or two sides of carbon steel sheet. This continuous electrolytic coating process can be used to apply the coating onto the surface of the steel sheet with an exceptionally uniform thickness.

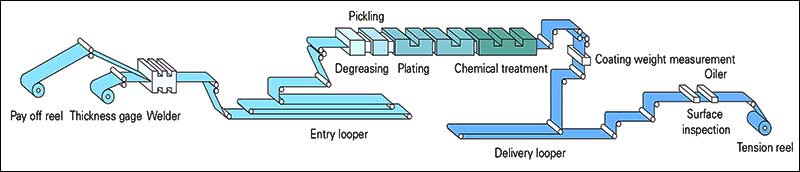

Electrogalvanization is the use of electrolytic equipment to degrease and pickle the workpiece into a solution containing a zinc salt, and connect the negative electrode of the electrolytic equipment; place a zinc plate on the opposite side of the workpiece to connect the positive electrode of the electrolytic equipment, and turn on the power With the directional movement of the current from the positive electrode to the negative electrode, a layer of zinc will be deposited on the workpiece.

Electro-galvanizing Methods

1.Cyanide galvanizing

Because cyanide is highly toxic, environmental protection puts forward strict restrictions on the use of cyanide in electroplating zinc, and continuously promotes the development of reducing and replacing cyanide electroplating baths, requiring the use of low-cyanide (or micro-cyanide) plating baths. But after electroplating with this process, the product quality is good.

2.Zincate galvanizing This process is evolved from cyanide zinc plating. Zincate zinc plating, which is an alkaline additive, has a pH of 12.5~13. Using this process, the coating lattice structure is columnar, with good corrosion resistance. 3.Chloride galvanizing This process is widely used in the electroplating industry, and zinc can be substituted for chromium after passivation. 4.Sulfate galvanizing This process is suitable for continuous galvanizing and has low cost

Main Features

1.Good corrosion resistance, fine and uniform combination, not easy to be corrosive gas or liquid into the interior.

2.Because zinc layer is relatively pure, it is not easy to be corroded in acid or alkali environment. Protect the steel body effectively for a long time.

3.After chromic acid passivation, it can be used in various colors. It can be selected according to customers’ preference. The galvanizing is beautiful and decorative.

4.The zinc coating has good ductility and will not easily fall during various bending, handling and impact.

The difference between electro galvanizing and hot galvanizing

1.There is a big difference in the amount of galvanizing between hot-dip galvanized sheet and electro-galvanized sheet. The amount of hot-dip galvanized sheet cannot be too small. Generally, the minimum is 50-60g / m2 on both sides, and the maximum is 600g / m2. The galvanized layer of the electro galvanized sheet can be very thin, the minimum is 15g / m2.

2. Hot-dip galvanized sheet and electro-galvanized sheet are fundamentally different in the coating structure. There is a slightly brittle compound layer between the pure zinc coating of the hot-dip galvanized sheet and the steel strip substrate. When the pure zinc coating crystallizes, zinc flowers are mostly formed, and the coating is uniform and free of pores. The zinc atoms of the electro galvanized sheet layer are only deposited on the surface of the steel strip, and they are attached to the surface of the steel strip by physical action.

Latest News

Contact Us

Name: Vincent Ding

E-mail: [email protected]

WeChat: 18633130786

Whatsapp: +8618633130786

WhatsApp

WhatsApp  Mail inquiry

Mail inquiry